A

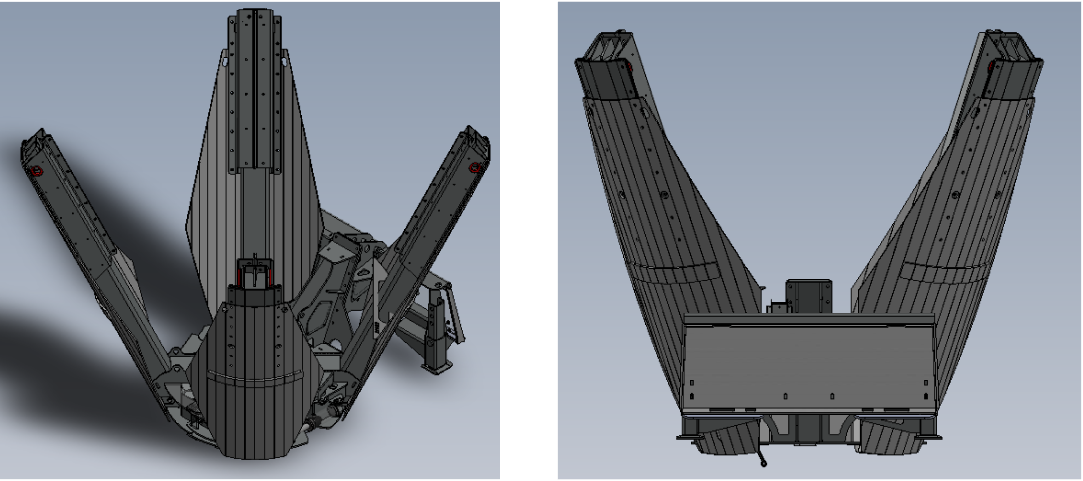

leading heavy machinery manufacturer from North American region was entrusted with a critical project to introduce a new machinery to move smaller sized trees from one location to another without damaging the tree as Trees are the anchor to any landscape, providing shelter, shade, and beauty.

_____________________

Challenges

Lack of Technical Data:

The client could only give us the Root ball diameter as a data from his end as his technical requirement and did not mention or provide us anything more specific on the technicality or functional parameters.

Lack of time:

Due to inadequate technical data, we were having the opening to choose the conceptual design from a huge variety of options leading us to consume more time in finalizing the conceptual design.

Competitive market:

As there were similar existing products available in the existing market, we also had a challenge to design the product in such a way that it should outrun the current models in terms of both functionality and user experience.

Environmental Impact:

Minimizing the impact to the environment and complying with stringent environmental regulations.

Ergonomic Design:

Improving operator comfort and safety.

The client could only give us the Root ball diameter as a data from his end as his technical requirement and did not mention or provide us anything more specific on the technicality or functional parameters.

Lack of time:

Due to inadequate technical data, we were having the opening to choose the conceptual design from a huge variety of options leading us to consume more time in finalizing the conceptual design.

Competitive market:

As there were similar existing products available in the existing market, we also had a challenge to design the product in such a way that it should outrun the current models in terms of both functionality and user experience.

Environmental Impact:

Minimizing the impact to the environment and complying with stringent environmental regulations.

Ergonomic Design:

Improving operator comfort and safety.

_____________________

Approach

Study and Research on the existing market product:

There were several case studies taken in understanding and identifying the pros and cons on the existing product in the market so that we could rectify and build a new product considering those key points.

Systematic approach like PDCA:

Based on the observations from the study, several brainstorming ideas and conceptual designs were planned in the phase 1 and were developed conceptually to have a visual knowledge on the product which was supposed to be designed.

Phased Implementation:

To minimize disruptions, the implementation was carried out in carefully planned phases, ensuring a smooth implementation of the actual plan.

Sustainable material selection:

Our engineers incorporated sustainable materials in its construction, reducing the environmental footprint.

Conducting Quality controls and Analysis:

There were several quality controls and analysis processes to be undertaken before the final design is processed.

Communication is the key:

Never had we left our client hanging, we always give them updates on various phases of our approach and our design progress on a weekly basis and keeping the client on the loop to have a smooth phase progress.

There were several case studies taken in understanding and identifying the pros and cons on the existing product in the market so that we could rectify and build a new product considering those key points.

Systematic approach like PDCA:

Based on the observations from the study, several brainstorming ideas and conceptual designs were planned in the phase 1 and were developed conceptually to have a visual knowledge on the product which was supposed to be designed.

Phased Implementation:

To minimize disruptions, the implementation was carried out in carefully planned phases, ensuring a smooth implementation of the actual plan.

Sustainable material selection:

Our engineers incorporated sustainable materials in its construction, reducing the environmental footprint.

Conducting Quality controls and Analysis:

There were several quality controls and analysis processes to be undertaken before the final design is processed.

Communication is the key:

Never had we left our client hanging, we always give them updates on various phases of our approach and our design progress on a weekly basis and keeping the client on the loop to have a smooth phase progress.

_____________________

Conclusion

Operational Excellence:

Due to several case studies and research by our engineers, we were able to build a product with operational excellence by rectifying the existing drawbacks of the current product in the market.

More models, more business to the client:

Initially the client was having an idea of developing only one size of the tree spade. But by looking at the final design and the prototype functionality, the client was having ideas of creating more such models of different sizes.

Due to several case studies and research by our engineers, we were able to build a product with operational excellence by rectifying the existing drawbacks of the current product in the market.

More models, more business to the client:

Initially the client was having an idea of developing only one size of the tree spade. But by looking at the final design and the prototype functionality, the client was having ideas of creating more such models of different sizes.

_____________________

Client Testimonial

" We are extremely pleased with the approach and the output of ACUFORE’s strong team. Not only have they worked towards our requirement, but they also suggested many new ideas and improvements which was indeed solution oriented rather than just providing support to us. "