T

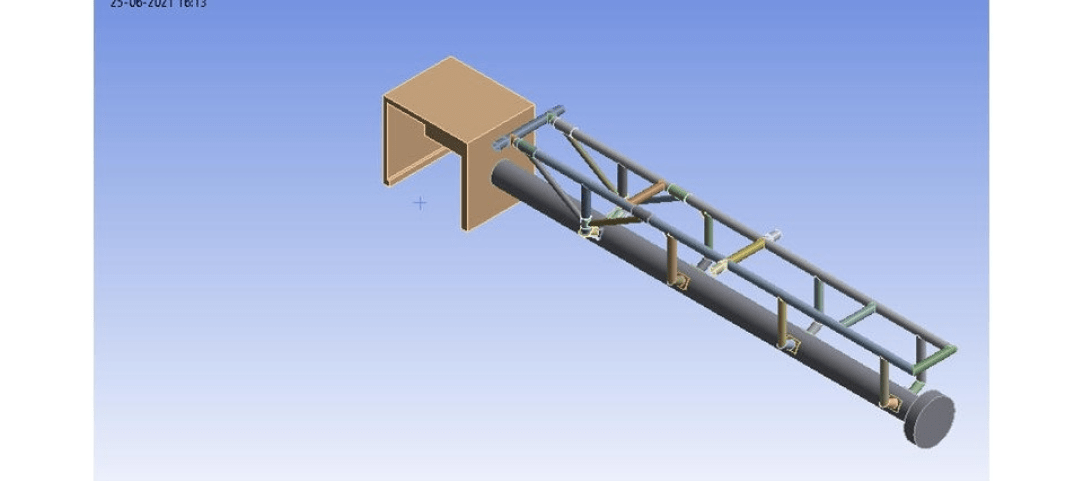

his project involves a meticulous evaluation and design process for the trunnions and lifting points of specific equipment, ensuring a secure and effective lifting method. The primary objective is to develop a subsea crash/lifting frame for the attached pig receiver. The scope encompasses a structural analysis of the unit using STADD, optimization of the support structure, thermal load analysis via ANSYS, and a comprehensive lifting lug analysis. The project adheres to industry-specific codes and standards, including DNV-ST-N00, DNV-OS-H205, and DNV-ST-N001 for Marine Operations and Marine Warranty.

_____________________

Challenges

Strength calculations carried out for the trunnions and lifting points on the below equipment to ensure it is an acceptable method of lifting. To design a subsea crash / lifting frame for the attached pig receiver, for the design and production of fabrication drawings.

_____________________

Approach

Project Scope:

• Structural analysis unit using STADD.

• To optimize the design of the Support Structure.

• Thermal Load analysis using ANSYS.

• Lifting lug analysis of unit using STADD.

Codes & Standards:

• DNV-ST-N00

• DNV-OS-H205

• DNV-ST-N001- Marine Operations and Marine Warranty

• Structural analysis unit using STADD.

• To optimize the design of the Support Structure.

• Thermal Load analysis using ANSYS.

• Lifting lug analysis of unit using STADD.

Codes & Standards:

• DNV-ST-N00

• DNV-OS-H205

• DNV-ST-N001- Marine Operations and Marine Warranty

_____________________

Conclusion

In conclusion, the project signifies a commitment to ensuring the reliability and safety of the lifting operations associated with the equipment. By employing advanced structural and thermal analysis tools such as STADD and ANSYS, the design process aims to optimize the support structure and enhance the overall efficiency of the subsea crash/lifting frame. Adherence to DNV codes and standards underscores a dedication to industry best practices, ensuring that the final fabrication drawings meet the highest levels of quality and compliance. This comprehensive approach reflects the project's commitment to excellence in subsea engineering and marine operations.

_____________________