A

leading heavy machinery manufacturer from North American region was entrusted with a critical project to procure mufflers for its latest diesel engine model. The company is committed to maintaining high-quality standards while optimizing costs. As a Costing Engineer, our role is critical in ensuring the selection of a cost-effective muffler supplier without compromising on quality.

_____________________

Challenges

The primary objective is to identify and procure mufflers that meet the stringent specifications for performance and durability while optimizing costs. The Costing Engineer supplies and conduct a comprehensive cost analysis, evaluating potential suppliers, and recommending the most economically viable option without compromising on quality.

Key Requirements:

• Technical Specifications:

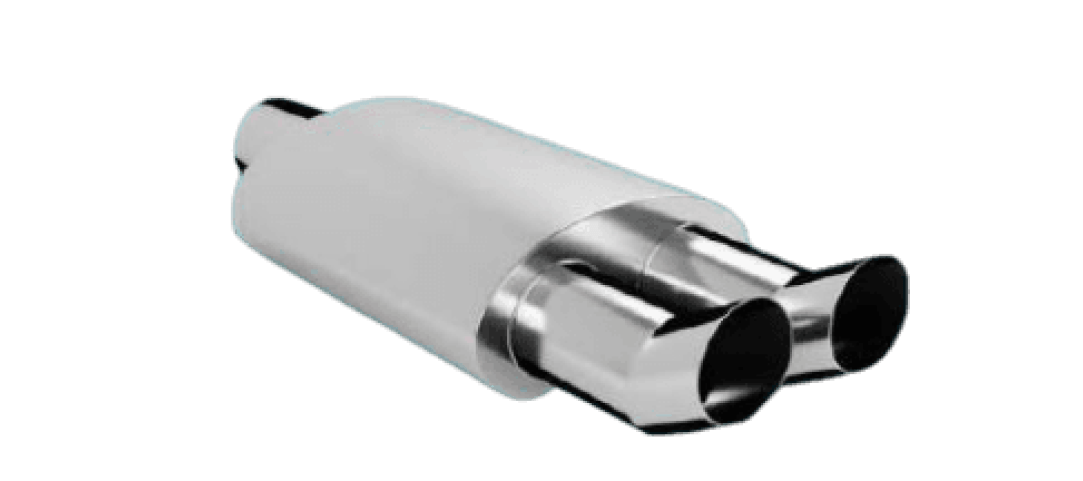

Understand the technical requirements of the muffler, including size, material, noise reduction capabilities, and compatibility with the diesel engine.

• Quality Standards:

Ensure that the selected muffler supplier adheres to industry quality standards and certifications.

• Cost Analysis:

Conduct a thorough cost analysis considering the initial purchase cost, transportation, installation, and potential maintenance costs.

• Supplier Evaluation:

Assess potential suppliers based on their reputation, reliability, past performance, and ability to meet delivery timelines.

• Life Cycle Costing:

Consider the total cost of ownership over the muffler's life cycle, including potential future maintenance and replacement costs.

_____________________

Approach

• Technical Specifications review:

a) Collaborate with the engineering

team to understand the specific technical requirements of the muffler.

b) Ensure alignment between technical

specifications and cost considerations.

• Quality Standards Assessment:

a) Identify industry standards

applicable to mufflers for diesel

engines.

b) Develop a checklist to evaluate

potential suppliers based on their

adherence to these standards.

• Cost Analysis:

a) Break down the cost elements

involved in the procurement process.

b) Explore opportunities for cost

optimization without compromising

quality.

c) Utilize historical data and industry

benchmarks for reference.

• Supplier Evaluation:

a) Develop a supplier evaluation matrix

based on factors such as reliability,

financial stability, past performance,

and reputation.

b) Collaborate with the procurement

team to gather relevant information

about potential suppliers.

• Life cycle Costing

a) Consider not only the initial

purchase cost but also long-term costs

associated with maintenance, repair,

and replacement.

b) Evaluate warranties and support

offered by suppliers.

_____________________

Conclusion

Based on the comprehensive analysis, we presented a recommendation to the procurement team, highlighting the selected supplier, the rationale behind the choice, and potential cost savings.

_____________________

Client Testimonial

" You really are a big help for all these tasks, I don’t know how we could get along without you.

To be clear, your plan is a great one to use when prices only go down, thanks a lot for thinking of that, I am very impressed.

It would be quite impossible for us to explore so many new suppliers as we do if it was not for the help of the Acufore costing team. "