I

ntroducing a sophisticated dual-channel controller designed to monitor and control up to two parameters simultaneously. This new device supports pH, ORP, conductivity, and flow measurements, with the addition of two new input options: Ion-Selective Electrode (ISE) and 4-20mA support. This versatility makes it ideal for a wide range of industrial applications, turning any toroidal sensor into a super toroidal sensor.

_____________________

Key Components

Dual Channel Monitoring and Control:

Capable of monitoring and controlling up to two parameters simultaneously, providing comprehensive real-time data. Supports pH, ORP, conductivity, and flow measurements, ensuring flexibility and accuracy in various applications.

New Input Options:

Includes two new input options: ISE and 4-20mA, expanding its usability to more specialized and precise applications. These inputs enhance the device's capability to handle a broader range of sensors and process signals.

Industrial Process Control:

Suitable for processes such as plating, chemical processing, pulp & paper, and mining.

Food and Beverage:

Ensures precise monitoring and control critical for maintaining quality and safety standards.

Municipal Water and Wastewater Treatment:

Ideal for monitoring and controlling pH and other parameters in water treatment facilities.

Industrial and Municipal Waste Treatment and Neutralization:

Provides accurate data for efficient waste treatment and neutralization processes.

Fume Scrubbers, HVAC, Cooling Towers, and Boilers:

Enhances operational efficiency and regulatory compliance.

Enhanced Sensor Capability:

This controller transforms any toroidal sensor into a super toroidal sensor, enhancing its performance and reliability. Ensures precise and stable measurements, crucial for maintaining optimal process conditions.

Capable of monitoring and controlling up to two parameters simultaneously, providing comprehensive real-time data. Supports pH, ORP, conductivity, and flow measurements, ensuring flexibility and accuracy in various applications.

New Input Options:

Includes two new input options: ISE and 4-20mA, expanding its usability to more specialized and precise applications. These inputs enhance the device's capability to handle a broader range of sensors and process signals.

Industrial Process Control:

Suitable for processes such as plating, chemical processing, pulp & paper, and mining.

Food and Beverage:

Ensures precise monitoring and control critical for maintaining quality and safety standards.

Municipal Water and Wastewater Treatment:

Ideal for monitoring and controlling pH and other parameters in water treatment facilities.

Industrial and Municipal Waste Treatment and Neutralization:

Provides accurate data for efficient waste treatment and neutralization processes.

Fume Scrubbers, HVAC, Cooling Towers, and Boilers:

Enhances operational efficiency and regulatory compliance.

Enhanced Sensor Capability:

This controller transforms any toroidal sensor into a super toroidal sensor, enhancing its performance and reliability. Ensures precise and stable measurements, crucial for maintaining optimal process conditions.

_____________________

Project Execution

Schematic Capture:

The project begins with the schematic capture phase, where the electrical connections and components are meticulously defined. Advanced schematic capture software is utilized to create detailed circuit diagrams, ensuring accurate interfacing of all components.

PCB Layout Design:

Following schematic capture, the PCB (Printed Circuit Board) layout design phase involves strategically placing components and routing connections on the board. The layout is optimized for signal integrity, power distribution, and thermal management to ensure reliable operation in various industrial environments.

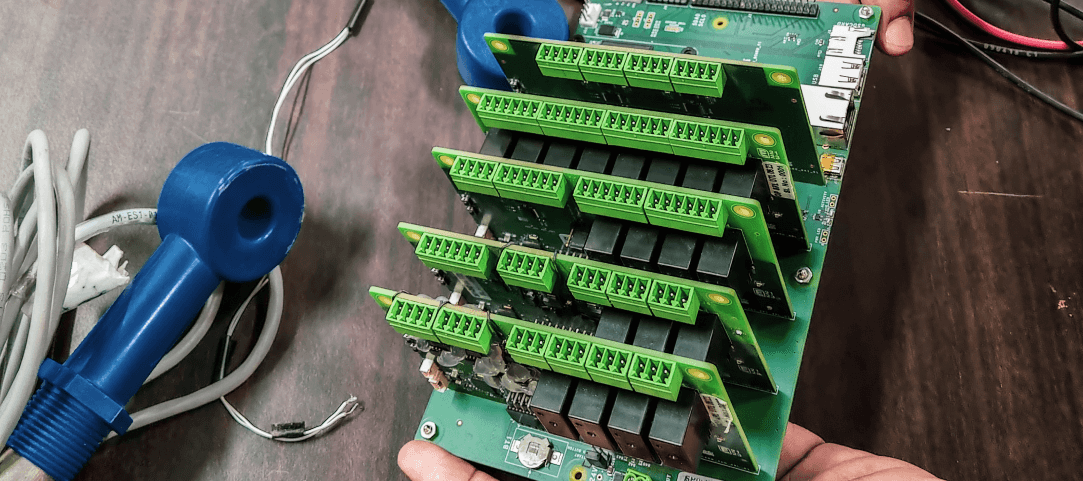

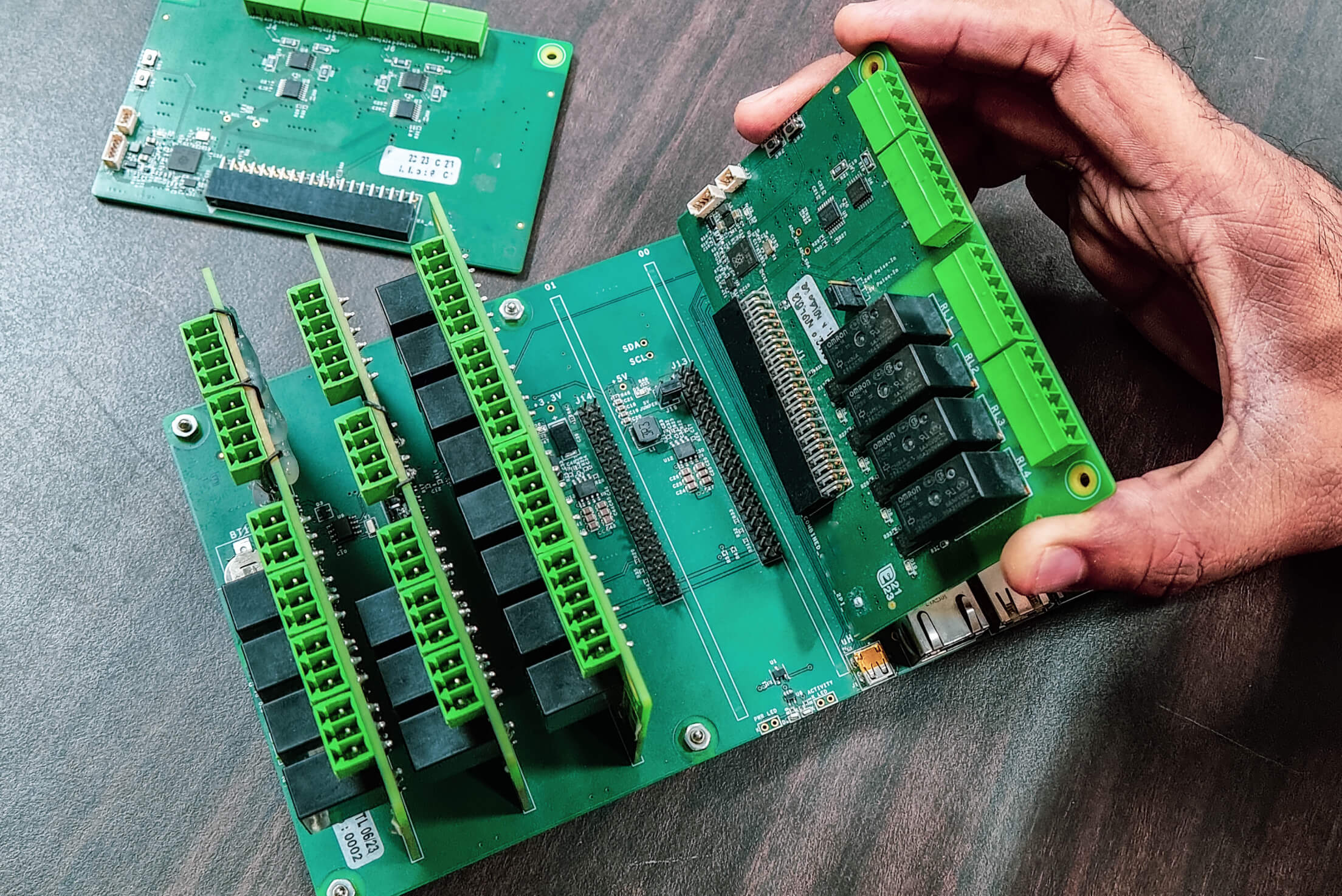

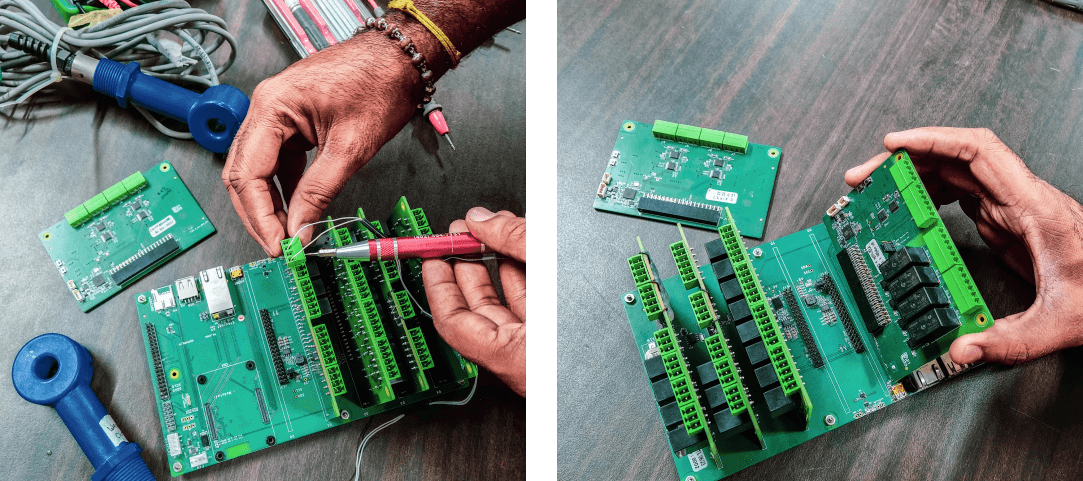

Prototype Build:

After finalizing the PCB design, prototypes are built to validate the design and functionality. Prototypes undergo rigorous testing, including functional tests, environmental tests, and performance evaluations. Any issues identified during testing are addressed, and the design is iterated until it meets all requirements and specifications.

The project begins with the schematic capture phase, where the electrical connections and components are meticulously defined. Advanced schematic capture software is utilized to create detailed circuit diagrams, ensuring accurate interfacing of all components.

PCB Layout Design:

Following schematic capture, the PCB (Printed Circuit Board) layout design phase involves strategically placing components and routing connections on the board. The layout is optimized for signal integrity, power distribution, and thermal management to ensure reliable operation in various industrial environments.

Prototype Build:

After finalizing the PCB design, prototypes are built to validate the design and functionality. Prototypes undergo rigorous testing, including functional tests, environmental tests, and performance evaluations. Any issues identified during testing are addressed, and the design is iterated until it meets all requirements and specifications.

_____________________

Conclusion

The new dual-channel controller is a versatile and powerful tool designed to meet the demanding requirements of various industrial applications. By supporting pH, ORP, conductivity, flow, ISE, and 4-20mA inputs, it provides comprehensive monitoring and control capabilities. The project execution, from schematic capture to PCB layout design and prototype build, ensures a reliable and high-performing solution. This controller's ability to turn any toroidal sensor into a super toroidal sensor further enhances its value, making it an indispensable device for modern industrial process control.

_____________________