L

ift tables are versatile devices used in various industries to facilitate lifting, positioning, and transporting of heavy materials. This case study explores the comprehensive design process of a lift table, detailing each phase from initial concept to final product. A North American Heavy Machinery manufacturing company approached us to design 3 variants of lift tables each of various load capacities and different height ranges.

_____________________

Challenges

•Ensuring the lift table can handle the maximum specified load without compromising safety or performance.

•Achieving a wide range of height adjustments while maintaining the stability of the lift table at all levels.

•Incorporating comprehensive safety features to protect users during operation.

•Balancing the need for mobility with the requirement for stability.

•Designing a high-quality lift table while keeping production costs within budget.

•Ensuring the lift table meets all relevant safety and quality standards.

•Achieving a wide range of height adjustments while maintaining the stability of the lift table at all levels.

•Incorporating comprehensive safety features to protect users during operation.

•Balancing the need for mobility with the requirement for stability.

•Designing a high-quality lift table while keeping production costs within budget.

•Ensuring the lift table meets all relevant safety and quality standards.

_____________________

Approach

Requirement Analysis:

The first step involves understanding the specific needs and constraints. This involves achieving the load capacity, Height range, Platform size, Mobility, and source of power.

Conceptual Design:

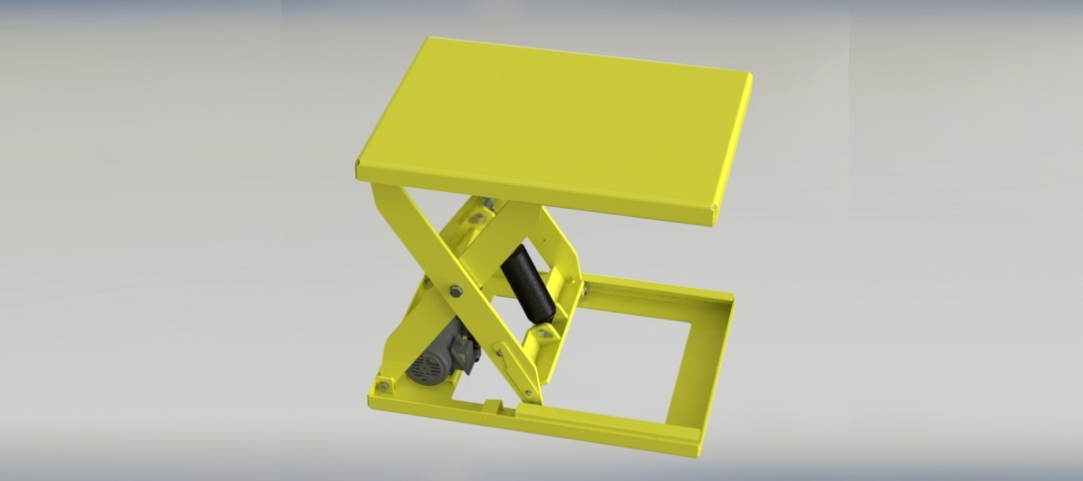

In this phase, rough sketches and basic models are created to visualize the lift table. The focus is on the overall structure and mechanism. The idea of scissor mechanism along with hydraulic actuator within the guidelines of safety regulations.

Precision Engineering Design:

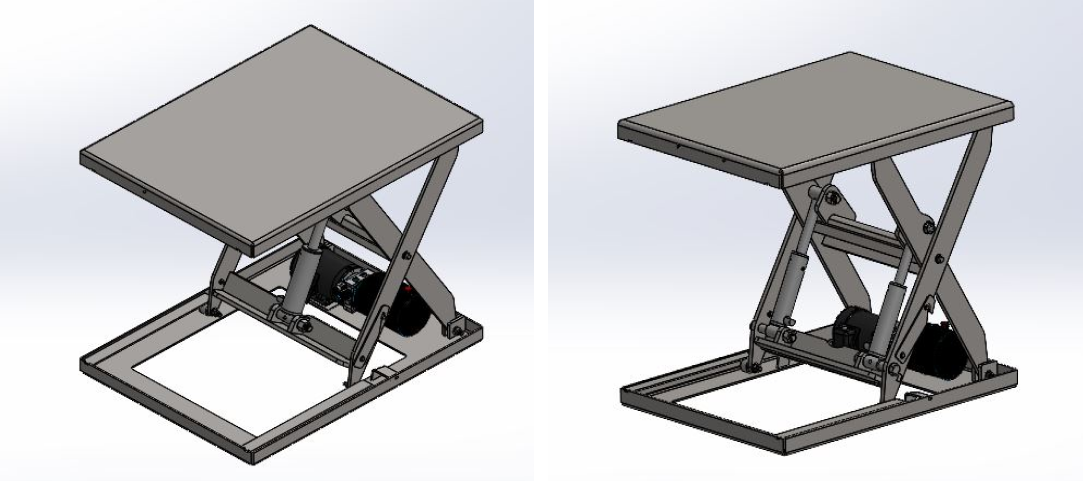

Once the concept is finalized, Using CAD software, detailed drawings and 3D models are developed. Parts such as Base Frame, Scissor Arms, Actuator, and control system (Sourced from a supplier based on our requirement) are designed in detail in this stage.

Engineering Analysis:

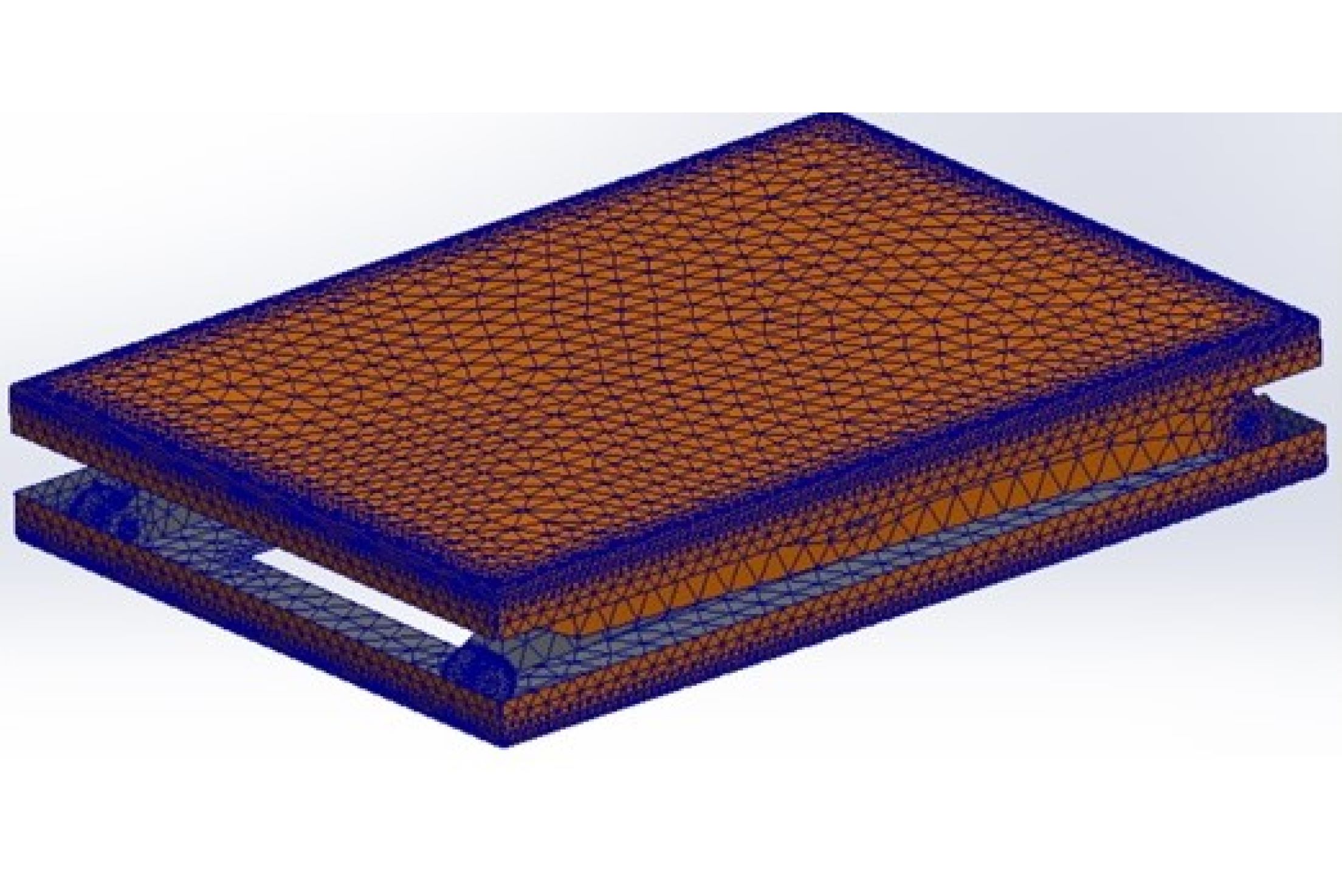

Conducting Static load analysis, Operational testing, and simulation to validate the structural integrity and performance of critical components.

Addition of structural reinforcements:

To optimize and to improve the overall strength and the performance of the lift table, updating and improving the design with respect to the Engineering Analysis results is mandatorily followed.

Communication to the client:

This step is performed and followed through every milestone of the project. The client input plays a significant and a vital role in enhancing the overall system as per his taste and requirement.

The first step involves understanding the specific needs and constraints. This involves achieving the load capacity, Height range, Platform size, Mobility, and source of power.

Conceptual Design:

In this phase, rough sketches and basic models are created to visualize the lift table. The focus is on the overall structure and mechanism. The idea of scissor mechanism along with hydraulic actuator within the guidelines of safety regulations.

Precision Engineering Design:

Once the concept is finalized, Using CAD software, detailed drawings and 3D models are developed. Parts such as Base Frame, Scissor Arms, Actuator, and control system (Sourced from a supplier based on our requirement) are designed in detail in this stage.

Engineering Analysis:

Conducting Static load analysis, Operational testing, and simulation to validate the structural integrity and performance of critical components.

Addition of structural reinforcements:

To optimize and to improve the overall strength and the performance of the lift table, updating and improving the design with respect to the Engineering Analysis results is mandatorily followed.

Communication to the client:

This step is performed and followed through every milestone of the project. The client input plays a significant and a vital role in enhancing the overall system as per his taste and requirement.

_____________________

Conclusion

Designing a lift table involves meticulous planning and attention to detail to ensure it meets all functional and safety requirements. Thus, by addressing the challenges and through carefully following a structured design process and focusing on quality, the final design can meet and exceed the industry standards and customer expectations. This ensures that the lift table is not only functional and efficient but also safe and durable, making it a valuable tool in industrial applications.

_____________________

Client Testimonial

" We were lacking time to design this lift table from scratch and launch this product under our banner with different load capacities and so we were looking for outsourcing consultants and I believe I found the best in the market. I am glad the design met my expectation, especially within the stipulated time frame made me even more delighted. With its robust construction and high load capacity, I am confident this lift table will stand-out in its market segment. Our journey will continue for many years turning different ideas into products. Kudos to the entire ACUFORE team! "