T

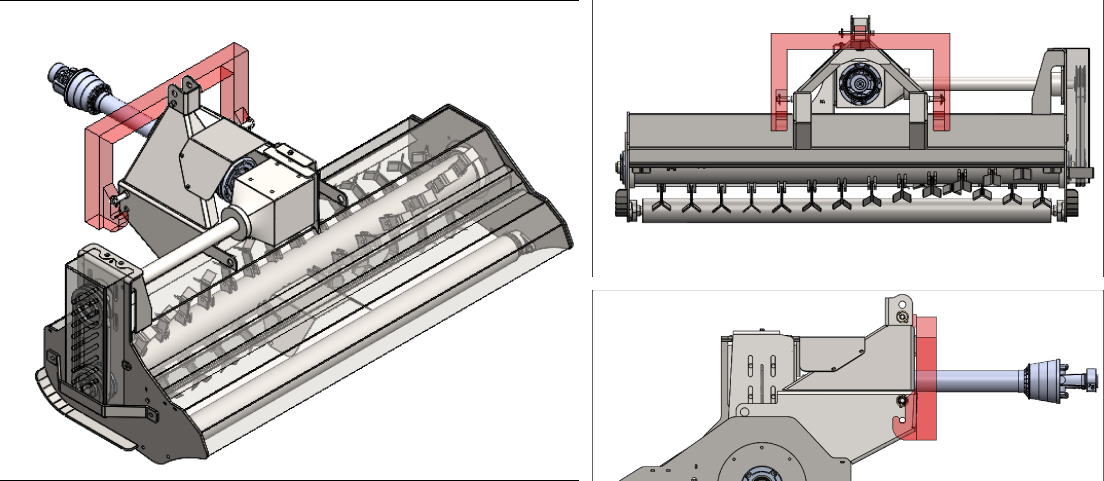

his case study explores the mechanical design modifications to convert a flail mower initially having a skid-steer mount into one compatible with a tractor mount for a North American Heavy Machinery Manufacturer. A Brief about the Flail Mower, they are essential agricultural and landscaping tools used for cutting vegetation and managing overgrowth. Typically mounted on various machines, the flail mower’s compatibility with different mounts can enhance its versatility. This case study showcases the conversion process from a skid-steer mount to a tractor mount, focusing on the design modifications achieving seamless integration and optimal performance.

_____________________

Challenges

The primary challenge was adapting the existing skid steer mounting bracket to fit a tractor’s three-point hitch system, which differs significantly in design and attachment points.

The hydraulic systems of skid steers and tractors often operate at different flow rates and pressures, leading to potential compatibility issues.

Modifying the mount and hydraulic system without compromising the flail mower's structural integrity was critical. The new mounting configuration also altered the weight distribution, necessitating additional reinforcement.

Ensuring the modified flail mower operated efficiently and safely when mounted on a tractor required comprehensive testing.

The hydraulic systems of skid steers and tractors often operate at different flow rates and pressures, leading to potential compatibility issues.

Modifying the mount and hydraulic system without compromising the flail mower's structural integrity was critical. The new mounting configuration also altered the weight distribution, necessitating additional reinforcement.

Ensuring the modified flail mower operated efficiently and safely when mounted on a tractor required comprehensive testing.

_____________________

Approach

Conceptual Design:

Generated multiple design concepts focusing on designing a new mounting bracket compatible with the tractor’s three-point hitch system.

Finalizing Design Concept:

Technical discussion internally within the team to identify and to evaluate feasibility, manufacturability, Performance, Ease of Use, and compliance with safety regulations. Also keeping in mind about the hydraulic system mountings so that it does not affect or hinder the system functionality.

Precision Engineering Design:

Created detailed engineering design drawings to ensure precise fabrication. Also conducted extensive load testing to identify any weak joints.

Engineering Analysis:

Conducted stress analysis, Fatigue testing and simulation to validate the structural integrity and performance of critical components.

Addition of structural reinforcements:

To optimize and to improve the overall strength and the performance of the mounting bracket, updating and improving the design with respect to the Engineering Analysis results is mandatorily followed. Thus, added structural reinforcements to areas identified as potential weak points.

Counterweights:

Designed counterweights to balance the modified flail mower and ensure stability during operation.

Communication to the client:

This step is performed and followed through every milestone of the project. The client input plays a significant and a vital role in enhancing the overall system as per his taste and requirement.

Generated multiple design concepts focusing on designing a new mounting bracket compatible with the tractor’s three-point hitch system.

Finalizing Design Concept:

Technical discussion internally within the team to identify and to evaluate feasibility, manufacturability, Performance, Ease of Use, and compliance with safety regulations. Also keeping in mind about the hydraulic system mountings so that it does not affect or hinder the system functionality.

Precision Engineering Design:

Created detailed engineering design drawings to ensure precise fabrication. Also conducted extensive load testing to identify any weak joints.

Engineering Analysis:

Conducted stress analysis, Fatigue testing and simulation to validate the structural integrity and performance of critical components.

Addition of structural reinforcements:

To optimize and to improve the overall strength and the performance of the mounting bracket, updating and improving the design with respect to the Engineering Analysis results is mandatorily followed. Thus, added structural reinforcements to areas identified as potential weak points.

Counterweights:

Designed counterweights to balance the modified flail mower and ensure stability during operation.

Communication to the client:

This step is performed and followed through every milestone of the project. The client input plays a significant and a vital role in enhancing the overall system as per his taste and requirement.

_____________________

Conclusion

Converting a flail mower from a skid-steer mount to a tractor mount involved overcoming significant design challenges related to mounting compatibility, hydraulic system adaptation, structural integrity, and performance testing. Through careful planning, engineering, and testing, these challenges were successfully addressed, resulting in a versatile and reliable piece of equipment.

_____________________

Client Testimonial

" We needed a solution that allowed our flail mower to be used with both skid steers and tractors, and this modification delivered exactly what we needed. The process was smooth, and the results exceeded our expectations. The hydraulic adjustments were spot on, and the structural reinforcements ensured that the mower could handle the tough landscaping tasks we face daily. This modification has expanded our operational capabilities and improved our productivity. A big thank you to the team for their hard work! "