O

ur esteemed client with over a decade of continuous collaboration in various successful projects, a North American automobile manufacturer, seeks to develop a new line of high-performance alloy wheels. The primary goals are to enhance the vehicle’s aesthetic appeal, improve performance, and ensure durability under various driving conditions.

_____________________

Challenges

1.

Achieving the right balance between strength and weight is critical. Alloy wheels must be lightweight to improve vehicle performance and fuel efficiency, yet strong enough to withstand various stresses and loads.

2. Designing the profile of the Alloy Wheel is crucial and determining the cornering load depending on the application of the alloy wheel is critical.

3. Designing an alloy wheel in compliance with stringent regulatory standards set by organizations like the Department of Transportation (DOT) and the society of Automotive Engineers (SAE).

4. Keeping in mind that the design of the Alloy wheel must be compatible with a range of vehicle models and types, considering differences in fitment, load ratings, and performance requirements.

5. Designing a durable Alloy Wheel. American consumers drive under a wide range of conditions, from smooth highways to rough off-road terrains. The alloy wheels must be durable enough to handle these variations.

6. Balancing the quality and performance of the alloy wheels with the need to keep the production costs competitive is a significant challenge.

2. Designing the profile of the Alloy Wheel is crucial and determining the cornering load depending on the application of the alloy wheel is critical.

3. Designing an alloy wheel in compliance with stringent regulatory standards set by organizations like the Department of Transportation (DOT) and the society of Automotive Engineers (SAE).

4. Keeping in mind that the design of the Alloy wheel must be compatible with a range of vehicle models and types, considering differences in fitment, load ratings, and performance requirements.

5. Designing a durable Alloy Wheel. American consumers drive under a wide range of conditions, from smooth highways to rough off-road terrains. The alloy wheels must be durable enough to handle these variations.

6. Balancing the quality and performance of the alloy wheels with the need to keep the production costs competitive is a significant challenge.

_____________________

Approach

1.

Design Specifications: The first step involves understanding the design specifications and technical requirements such as material, size and fitment, load rating and the application of the alloy wheel depending on its performance.

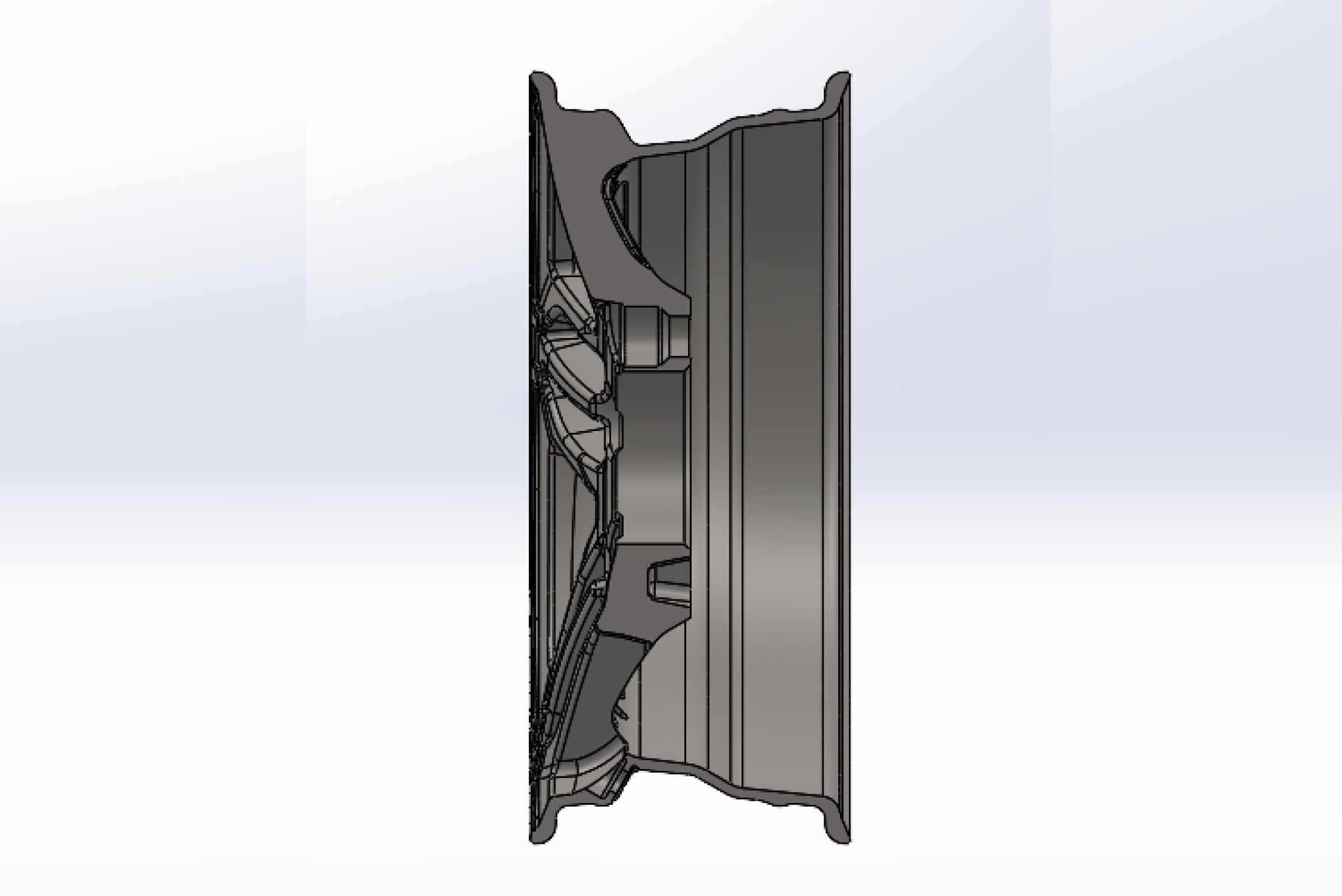

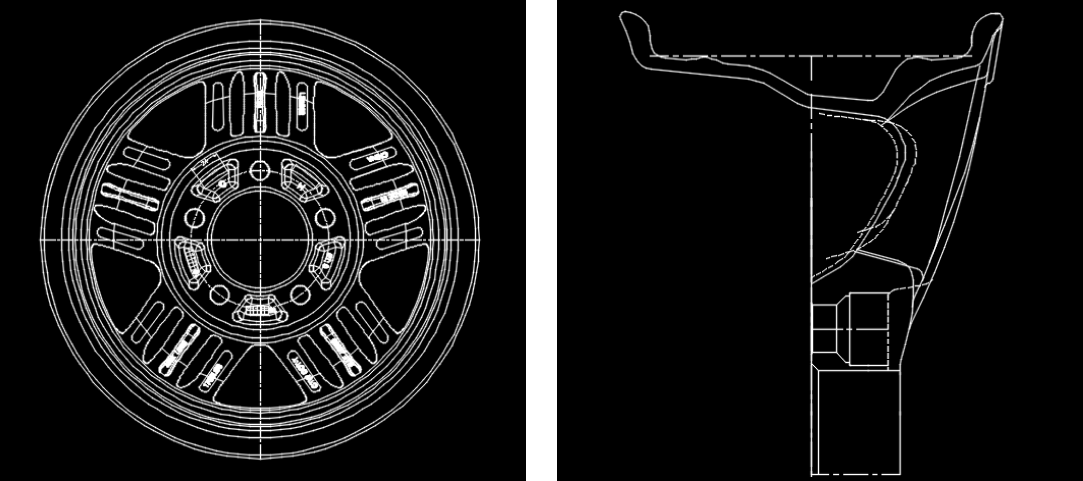

2. Conceptual Design: Develop multiple design sketches considering the client’s branding and aesthetic goals. Using CAD software, 3D models are created.

3. Engineering Analysis: Once the profile of the Alloy wheel is finalized, we simulate and optimize the structural integrity and performance of the design under various conditions such as cornering load, radial loads, impact load, and torsion load.

4. Adherence to Standards and regulations: Staying up to date with the latest regulations is very important. Ensure that the design parameters adhere to the country’s standards and regulations.

5. Communication to the client: Establish clear communication channels with the client and involve them in key stages of the design process. Regularly present design updates and prototypes for feedback and be prepared to make iterative adjustments based on their input.

2. Conceptual Design: Develop multiple design sketches considering the client’s branding and aesthetic goals. Using CAD software, 3D models are created.

3. Engineering Analysis: Once the profile of the Alloy wheel is finalized, we simulate and optimize the structural integrity and performance of the design under various conditions such as cornering load, radial loads, impact load, and torsion load.

4. Adherence to Standards and regulations: Staying up to date with the latest regulations is very important. Ensure that the design parameters adhere to the country’s standards and regulations.

5. Communication to the client: Establish clear communication channels with the client and involve them in key stages of the design process. Regularly present design updates and prototypes for feedback and be prepared to make iterative adjustments based on their input.

_____________________

Conclusion

By leveraging iterative design processes, and robust testing, it was possible to overcome challenges and deliver a product that meets high standards of the American automotive market. Effective communication and collaboration with the client throughout the process are essential to ensure the final product aligns with their expectations and requirements.

_____________________

Client Testimonial

" Your attention to detail and commitment to excellence was evident throughout the project. The way you listened to our needs and delivered the design of the alloy wheel that perfectly combined aesthetic appeal with high performance is truly appreciated. The final product is a testament to your skill, blending cutting-edge technology with sophisticated design. The ability of the Design Team to meet tight deadlines and maintain quality standards was truly impressive! "